Magnets and magnet systems

Application examples and technical information of permanent and electro magnetic chucks

The Beloh standard range offers a wide range of permanent ceramic chucks in different designs and sizes.

The magnetic systems are characterised by an even distribution of the magnetic holding power over the entire chuck surface with better magnetic stability.

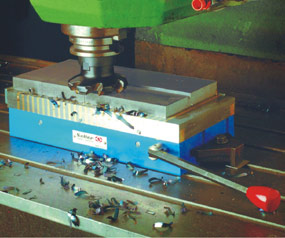

The chucks are used for grinding, milling, shaping and drilling, etc. The chucks can equally be used on electra discharge machines.

Magnetic chucks offer considerable advantages compared to traditional work holding methods:

- short set up and break down times,

- precise and simple alignment,

- easy and distortion-free holding of workpieces,

- optimum machining of all sides except for the holding face,

- stop strips increase the options,

- clamping lugs and other auxiliary fixtures are dispensed with.

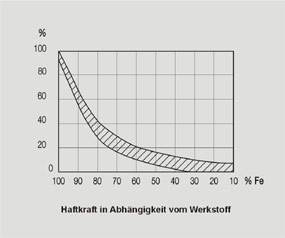

All ferrous materials can be held. Workpieces with high iron contents increase the holding power.

The shape and dimensions determine the choice of the chuck design.

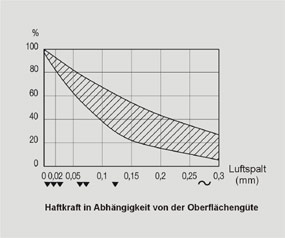

The workpiece clamping surface affects the holding power. The more pole spaces which are covered by the workpiece, the better will be the holding power. The workpiece to be machined must cover at least one pole step.

In selecting the chuck, the mode of machining, the workpiece size and thickness must be taken into consideration.

The magnetic field is brought into play by shifting the switch lever.

Special magnetic systems are available as standard for the most varied tasks:

• Permanent magnetic chucks and circular chucks for grinding purposes.

• Permanent magnetic chucks and circular chucks with increased magnetic power for heavy machining.

• Permanent magnetic chucks with fine pole spacing for the machining of workpieces less than 5 mm thick and with very small holding surfaces.

• Permanent magnetic chucks with sine table with single or double swivelling movement.

All magnetic chucks have a particularly stable ceramic magnetic system and offer an unlimitedly constant holding power. The magnetic field which builds up during use is very smalI, and the residual magnetism resulting in the workpiece and tool is conse-

quently insignificant.