Magnets and magnet systems

Sine tables with permanent magnetic chucks with simply pivoted about the longitudinal axis and double pivoted about the longitudinal and transverse axis, designed for grinding processes

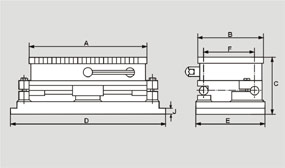

- with simply pivoted about the longitudinal axis

Technical features of the permanent magnetic chucks see here.

Features of the sine table:

- Low height

- Slip gauges can be set up to 45°; the table can be turned up to 90°

- The contact surface for gauge blocks lies on the 0 line and thus enables the setting

of very small angles

- An angle can be set to within +/- 10 seconds of a degree.

Pole spacing: Steel 6 mm / brass 1,5 mm / steel 2 mm / brass 1,5 mm

* The shaft does not project from the chuck and can be handled using an Allen key.

Further dimensions on request.

Machining of the top plate possible without impairing the holding power (steel 15 mm / brass 7 mm). Attechment of the sine tables to the machining table by means of clamping lugs. The chuck is fixed to the processing machine with clamping lugs.

Two end stops are supplied as standard.

Note: If necessary, the magnetic chucks can be fitted with an additional safety switch.

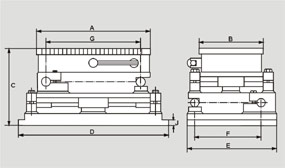

- double pivoted about the longitudinal and transverse axis

Currently not available!Technical features of the permanent magnetic chucks see here.

Pole spacing: Steel 6 mm / brass 1,5 mm / steel 2 mm / brass 1,5 mm

Further dimensions on request.

Machining of the top plate possible without impairing the holding power (steel 15 mm / brass 7 mm). Attechment of the sine tables to the machining table by means of clamping lugs. .

The chuck is fixed to the processing machine with clamping lugs.

Two end stops are supplied as standard.

Note: If necessary, the magnetic chucks can be fitted with an additional safety switch.