Magnets and magnet systems

Demagnetisers

Demagnetisers tabletop models

This demagnetiser is ideal for workshops as it removes the remaining magnetism from components, tools, screws, bearings, etc. The piece to be demagnetised should be passed over the device.

- Equipped with illuminated on-off switch, thermostat and connecting cable with plug. This model is not designed for continuous use and cannot be connected for more than 10 minutes at one time. It has a thermostat that disconnects its when it reaches the maximum permitted temperature (70ºC); it cannot be reconnected until the temperature has dropped to the permitted levels.Input voltage: 220-240 V / 50-60 Hz.

- Equipped with illuminated on-off switch, thermostat and connecting cable with plug. This model is not designed for continuous use and cannot be connected for more than 10 minutes at one time. It has a thermostat that disconnects its when it reaches the maximum permitted temperature (70ºC); it cannot be reconnected until the temperature has dropped to the permitted levels.Input voltage: 220-240 V / 50-60 Hz. - Equipped with illuminated on-off switch and connecting cable with plug.

- Equipped with illuminated on-off switch and connecting cable with plug. The demagnetisers is suitable for continuous use (100% ED). Input voltage: 220-240 V / 50-60 Hz.

Demagnetisers portable model

This model is used to remove the remaining magnetism from large pieces. The device should be passed over the piece manually.

This demagnetiser is not designed for continuous use and cannot be connected for more than 10 minutes at one time.

It has a thermostat that disconnects its when it reaches the maximum permitted temperature (70ºC); it cannot be reconnected until the temperature has dropped to the permitted levels.

Equipped with on / off switch, integrated signal lamp, thermostat and connecting cable with plug.

Input voltage: 220-240 V / 50-60 Hz.

Demagnetisers portable model (DISCONTINUED MODEL)

This model is used to remove the remaining magnetism from large pieces. The device should be passed over the piece manually.

This model is used to remove the remaining magnetism from large pieces. The device should be passed over the piece manually.This demagnetiser is not designed for continuous use and cannot be connected for more than 10 minutes at one time.

It has a thermostat that disconnects its when it reaches the maximum permitted temperature (70ºC); it cannot be reconnected until the temperature has dropped to the permitted levels.

Equipped with on / off switch, integrated signal lamp, thermostat and connecting cable with plug.

Input voltage: 220-240 V / 50-60 Hz.

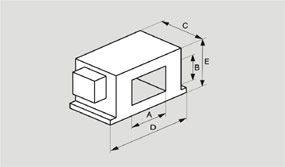

Demagnetisers tunnel models

This demagnetiser is designed for continuous use (100% ED), it can be connected permanently.

This model is suitable for automatic processes where there is a flux of material. The pieces to be demagnetised should be passed through the inside of the device.

Equipped with signal lamp, on / off switch and connecting cable with plug.

Input voltage: 220-240 V / 50-60 Hz. Other voltages on request.

Customised models and measurements on request.

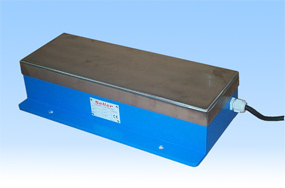

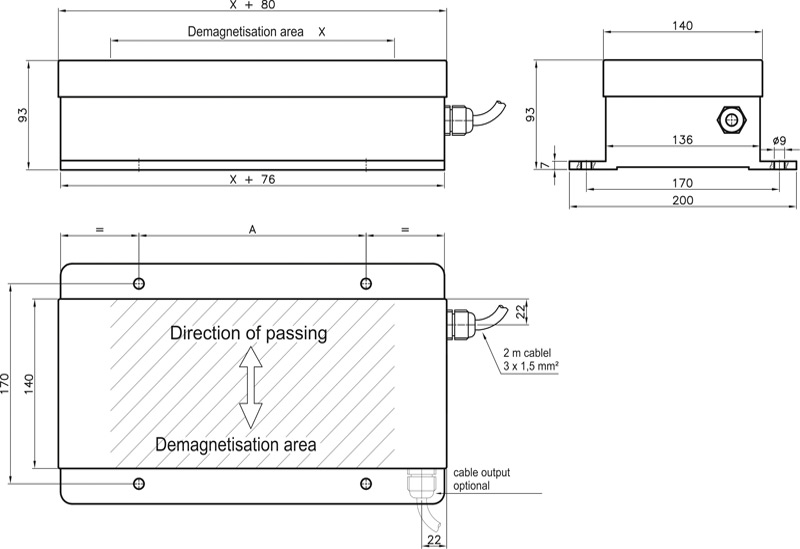

Continuous service demagnetisers

During the manufacturing process of pieces in series, they are frequently subjected to a magnetic field and catch some remanent magnetism. In most situations, to continue or finish production of these pieces, magnetism must be removed. The most suitable is to use a continuous service demagnetiser.

During the manufacturing process of pieces in series, they are frequently subjected to a magnetic field and catch some remanent magnetism. In most situations, to continue or finish production of these pieces, magnetism must be removed. The most suitable is to use a continuous service demagnetiser. - Rectangular: which are generally placed under the conveyer belt.

Equipped with 2 m connection cable (3 x 1,5 mm ²).

Input voltage: 220-240 V / 50-60 Hz.

Futher dimensions on request.