Magnets and magnet systems

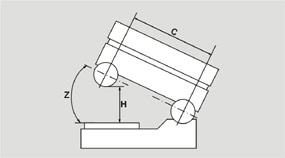

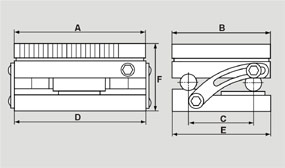

Precision Sine tables with permanent magnetic chuck with fine transverse pole simply pivoted about the longitudinal axis and double pivoted about the longitudinal and transverse axis

- Simply pivoted about the longitudinal axis

Neodymium magnet systems (rare earth),

all steel construction and low height (77 mm)

These precision sine tables are especially suitable for the very accurate grinding of work-pieces with non-parallel sides. The angles can set by using the end guides.

A list of sine values is included.

To prevent unwanted movement during the operation, the table has to be locked on the central axis.

Characteristics of the sine tables:

• all steel construction (HRC 55)

• very low height

• end guides can be set up to 45°

• the contact point for the end guides is 2 mm under the 0-line and makes the setting of very small angles possible

• setting the angles can be achieved to an accuracy of ± 5 sec.

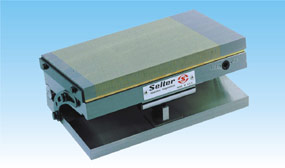

The extremely powerful Neodymium magnetic systems in combination with fine pole spacing (steel 1.5 mm / brass 0.8 mm) offers a wide range of application possibilities especially for clamping very thin and small pieces of work.

The solid construction of the case and the stable hard-soldered top plate, together with the powerful magnet system, guarantees an extremely long and trouble-free life.

All these types of chucks have a detachable handle. Undesirable magnetisation of machine parts is prevented because the field lines do not exceed 10 mm.

These types of chucks can also be used on spark erosion machines.

Pole spacing: Steel 1,5 mm / brass 0,8 mm

Holding power: max. 70 - 80 N/cm² (≙ 7 - 8 kg/cm²)

Other measurements on request.

Machining the top plate to a depth of 5 mm is possible without affecting the holding power.

The chuck is fixed to the processing machine with clamping lugs. Two end stops are supplied as standard.

Example

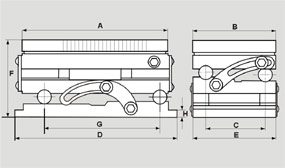

- double pivoted about the longitudinal and transverse axis

Technical features and equipment as the product description for precision sine table with single pivot (see above) and permanent magnetic chucks with fine pole spacing

Pole spacing: Steel 1,5 mm / brass 0,8 mm

Other measurements on request.

Machining the top plate to a depth of 5 mm is possible without affecting the holding power. The chuck is fixed to the pracessing machine with clamping lugs.

Two end stops are supplied as standard.