Magnets and magnet systems

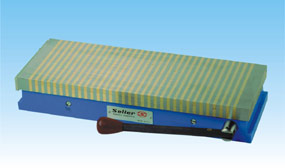

Permanent magnetic chucks with transverse pole spacing designed for grinding processes

The chucks was designed specifically for machining on surface grinding machines.

The chucks was designed specifically for machining on surface grinding machines.A powerful permanent ceramic magnet system, a close pole step and the small overall height makes ist usable for a large numer of tasks.

The design of the cast iron basic section and the hardsoldered top plate, as well as a ceramic magnet system, ensure an extremely long and maintenance-free life.

The magnet systems can also be used to spark erosion machines.

Curve of lines of force: approx. 8 mm above the pole plate, consequently no magnetisation of the tools

Pole spacing: Steel 6 mm / Brass 5 mm

Holding power: max. 80 - 100 N/cm² (≙ 8 - 10 kg/cm²)

Product video

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

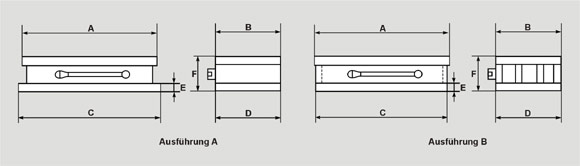

* The shaft does not project from the chuck and can be handled using an Allen key.

Further dimensions on request.

Machining of the upper plate possible without impairing the holding power (steel 15 mm / non-ferrous 7 mm). The execution to 300 x 150 mm are supplied with removable levers. Attachment of the chucks to the machining table by means of clamping lugs. The chucks are supplied with 2 stops as standard.

Note: If necessary, the magnetic chucks can be fitted with an additional safety switch.