Separation Systems

Industrial separation systems

Plate magnets, type FDA and type FDB

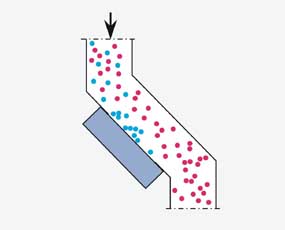

Plate magnets are used for removing ferrous materials from material flows on conveyor belts, during free-fall, in vertical or sloping pipelines, under chutes and slides, etc.

Plate magnets, type FDA

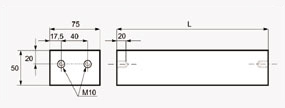

This type of plate magnet is fitted with powerful ceramic magnets mounted in such a way that an extra strong, deep magnetic field is generated (see table). The surfaces of the magnet that can come in contact with the material flow are made of stainless steel (AISI 304). This type of plate magnet is fitted with a steel plate on the rear with threaded holes for installation. The standard range includes magnets in a large number of different sizes - almost any size can be supplied on order.

This type of plate magnet is fitted with powerful ceramic magnets mounted in such a way that an extra strong, deep magnetic field is generated (see table). The surfaces of the magnet that can come in contact with the material flow are made of stainless steel (AISI 304). This type of plate magnet is fitted with a steel plate on the rear with threaded holes for installation. The standard range includes magnets in a large number of different sizes - almost any size can be supplied on order.To make cleaning the plate magnets quick and thorough, they can be supplied with a cleaning tray which can be either manually or pneumatically operated. The pneumatic operation could be used to advantage when the magnet is installed in a position that is difficult to reach. The pneumatic operation meets all ISO and CETOP standards.

Depth of effective magnetic field - plate magnetsAll dimensions in mm.

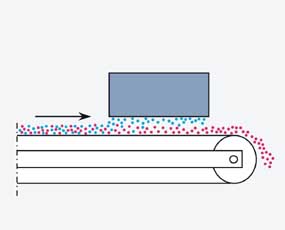

FDA plate magnets above material on a conveyor belt

FDA plate magnets above material on a conveyor belt  In this application, the material flow comes directly in contact with the plate magnet.

In this application, the material flow comes directly in contact with the plate magnet.Product video

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

Plate magnets, type FDA, with ceramic magnet systems

Plate magnets, type FDA, with Neodymium magnet systems

Plate magnets equipped with the powerful Neodymium magnetic material are used when a relatively large depth of magnetic field is needed. This can be the case, for example, when very small ferrous particles (< 5 μ) have to be separated from material flows.

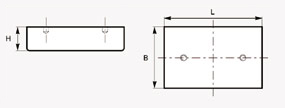

Plate magnets, type FDB

This type of plate magnet is normally used to remove ferrous particles from raw materials during textile production.