Separation Systems

Industrial separation systems

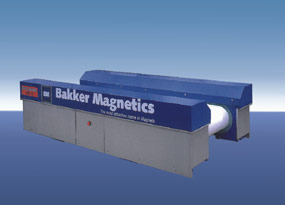

Eddy Current metal separation systems for the waste disposal and recycling industries

BM supplies the range of new generation Eddy Current non-ferrous metal separation systems for use in, for example, the waste disposal and recycling industries. Through the introduction of a completely new 18-pole magnet cylinder, the efficiency is greatly improved. In many applications, the separation can almost reach 100%. In recent tests in the glass recycling industry, the efficiency reached 99.8%.

As well as the new generation of Eddy Current metal separation systems, BM supplies systems equipped with the conventional 12-pole magnet cylinder. These systems are suitable for removing non-ferrous particles greater than 9 mm. The metal separators with the new generation magnet cylinder are optimised to separate particles greater than 2 mm.

The table below contains the standard range of Eddy Current systems. Systems with non-standard dimensions and/or specifications on request.

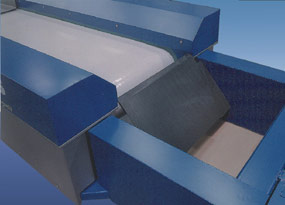

All non-ferrous metal separation systems are supplied as standard with:

- continuously adjustable conveyor belt speed from 0 to 2 m/s;

- continuously adjustable induction cylinder speed from 0 to 3000 rpm;

- conveyor belt with idlers equipped with dust seals on both sides;

- switch box for connection to the electricity supply;

- vibration sensors for detecting imbalances;

- double emergency stop switches on both sides of the machine;

- belt tracking control;

- internal magnet cylinder protected with the use of special plastics.

A detailed brochure about BM Eddy Current metal separation systems is available on request.