Separation Systems

Industrial separation systems

Overbelt magnet systems

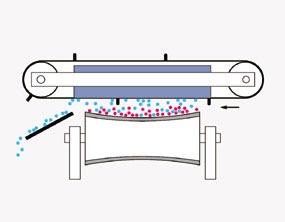

The most important application for overbelt magnet systems is ferrous metal separation from materials on conveyor belts. To do this, they are installed over the conveyor belt. The magnetic system lifts the ferrous particles from the material flow passing underneath and then drops them into a collection bin when they leave the magnetic field.

The most important application for overbelt magnet systems is ferrous metal separation from materials on conveyor belts. To do this, they are installed over the conveyor belt. The magnetic system lifts the ferrous particles from the material flow passing underneath and then drops them into a collection bin when they leave the magnetic field.The working surface of the magnets is protected by a stainless steel plate which absorbs any wear. This type of ferrous separation system is often used in industry to prevent ferrous particles damaging production machines such as shredders. A growing application area is the recycling industry often in combination with Eddy Current non-ferrous metal separators. The overbelt magnet systems are supplied in two main types, one using permanent magnets and the other electromagnets. Last mentioned for effective field depth > 500 mm.

This type of ferrous separation system is equipped with a powerful permanent magnet.

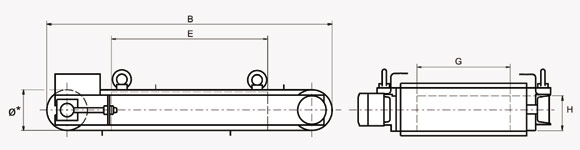

The standard drive for the overbelt magnet system (up to and including the 320 series) is a drum motor. On the 400 and 500 series, the standard drive is by means of a shaft-mounted reduction motor. If required, the belt on the 220 series can also be equipped with the same

sort of motor (add "/21" to the article number). The overbelt systems are equipped with a belt tensioner and because of the concave shape of the drums, the belt is self centring. The belt is made from synthetic rubber with vulcanised idlers. The electrical connections conform

to standard IP 54 or, if required, IP 65 and the standard power supply required is 3 x 380 V 50 Hz. Systems are available for other voltages if necessary. Some types can be supplied in a 'stretch' version. In these, a transport pole is added as a continuation of the main pole. This transport pole produces a change in the magnetic field which causes the ferrous particles on the belt to move so that any non-ferrous particles which had been hold by the iron articles can drop back into the material flow. This means there are fewer impurities in the ferrous collection. The 'stretch' versions can only be installed with the belt running in the same direction as the conveyor belt. In the 400 and 500 series, the rubber conveyor belt has a wear-resistant layer (Correx blue 45° shore) between the idlers.

Overbelt magnet system mounted transversely over the conveyor belt.

Overbelt magnet system mounted transversely over the conveyor belt.  Overbelt magnet system mounted longitudinally over the end roller of the conveyor belt.

Overbelt magnet system mounted longitudinally over the end roller of the conveyor belt.Effective depth of magnetic field - overband magnets

Overbelt magnet systems with ceramic magnet system

Series 135

*Magnet dimensions

Series 220

*Magnet dimensions

Series 320

*Magnet dimensions

Series 400

*Magnet dimensions

Series 500

*Magnet dimensions

Overbelt magnet systems with neodymium magnet system

Effective depth of magnetic field - overbelt magnets

*Magnet dimensions

Overbelt magnet systems multipole for longitudinally discharge

400 execution:

drive: geared motor, manufacturer SEW, power: 2,2 - 4 kW (depending on model)

500 execution:

drive: geared motor, manufacturer SEW, power: 3 - 5,5 kW (depending on model)