Separation Systems

Industrial separation systems

Cascade magnet systems

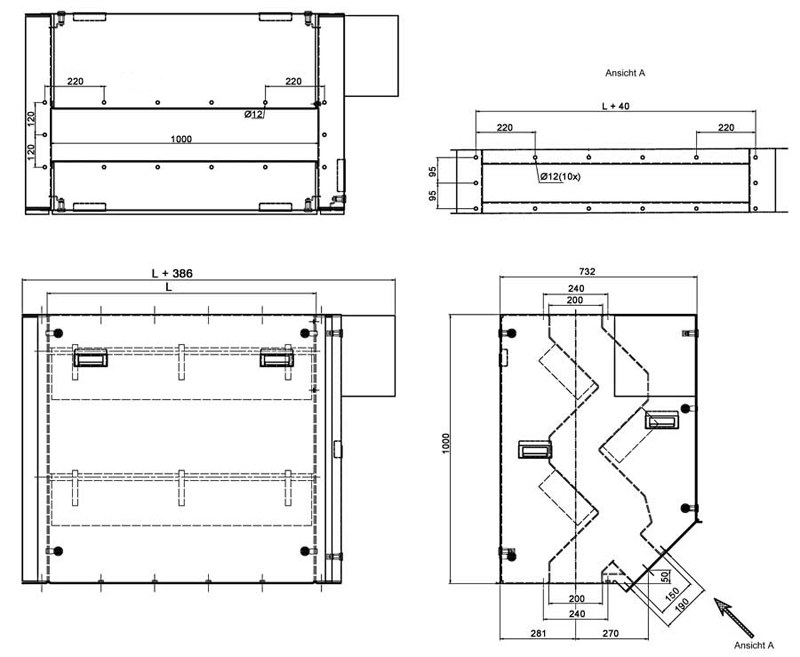

Cascade magnet systems are used in situations where ferrous particles have to be removed thoroughly from large quantities of raw materials. Cascade systems are available in automatic models and are strongly built with a 4 mm thick stainless steel or steel housing. The cascade systems have a wide range of uses and are easy to incorporate in existing systems. A valve box is built in to the cascade systems to remove the ferrous particles that have been collected. Once the valve box has been opened, the magnets can be turned away and the ferrous particles will then drop out of the system via the side exit. With the pneumatic versions, a push of a button is sufficient to remove all the ferrous particles collected in the valve box chamber. Optionally, this type can be supplied with an electrically operated valve. All the components of the pneumatic system conform to the ISO and CETOP standards. As an option, the automatic versions can be fitted with a pressure tank which enables the system to stay in service when the supply of air pressure is lost. If required, all models can be fitted with inspection windows and/or manganese steel wear plates. Cascade magnet systems are equipped with FDA magnets as standard. If required, they can also be supplied with FDL or FDL/C systems (additions and changes at extra cost).

Cascade magnet systems are used in situations where ferrous particles have to be removed thoroughly from large quantities of raw materials. Cascade systems are available in automatic models and are strongly built with a 4 mm thick stainless steel or steel housing. The cascade systems have a wide range of uses and are easy to incorporate in existing systems. A valve box is built in to the cascade systems to remove the ferrous particles that have been collected. Once the valve box has been opened, the magnets can be turned away and the ferrous particles will then drop out of the system via the side exit. With the pneumatic versions, a push of a button is sufficient to remove all the ferrous particles collected in the valve box chamber. Optionally, this type can be supplied with an electrically operated valve. All the components of the pneumatic system conform to the ISO and CETOP standards. As an option, the automatic versions can be fitted with a pressure tank which enables the system to stay in service when the supply of air pressure is lost. If required, all models can be fitted with inspection windows and/or manganese steel wear plates. Cascade magnet systems are equipped with FDA magnets as standard. If required, they can also be supplied with FDL or FDL/C systems (additions and changes at extra cost).

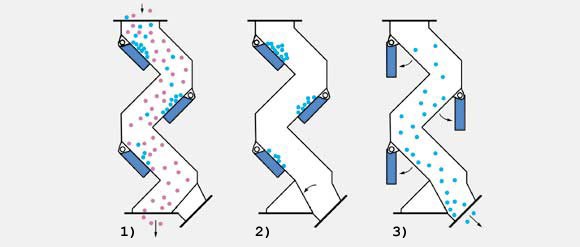

Operating principle of the Bakker Magnetics cascade magnet system:

1. The material flow passes the magnet system

2. To remove the ferrous contamination, the material flow is stopped and the flap valve turned

3. By rotating the magnets, the magnetic field is removed from the ferrous particles collected so they fall through the side opening to the outside.

Cascade magnet systems – permanent magnetic with closed / shielded pneumatic part and automatic cleaning

- Housing from 4 mm thick stainless steel (1.4301)

- with side-mounted valve box for outflow of separated iron particles

- with pneumatically actuated control valves

- Cascade magnet systems are equipped with FDA magnets as standard.

If required, they can also be supplied with FDL or FDL/C systems.

Further dimensions on request.