Separation Systems

Industrial separation systems

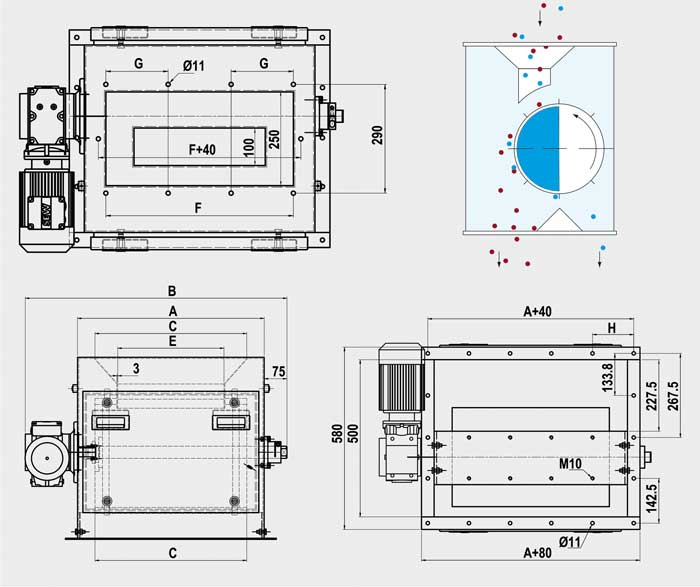

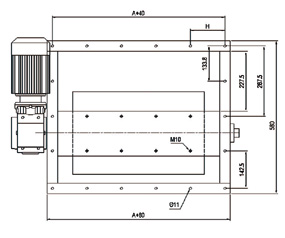

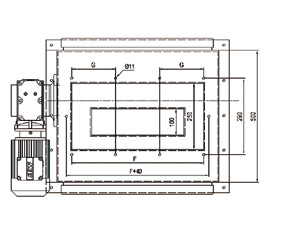

Permanent drum systems in housing

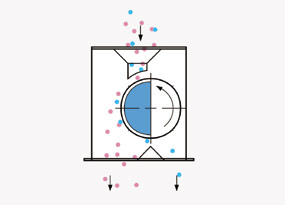

The drum magnet in housing, also called separation drum, contains two sectors: a magnetic and a non-magnetic sector. Around this system a drum rotates onto which the materials are dropped or passed on. For an effective removal, this drum is provided with idlers. The waste is fedd onto a magnetic sector of the drum. The magnetic field forces the

iron particles to remain longer on the drum. As they leave the drum further down, they can be collected separately.

This magnet system, comprising a drum magnet in a solid housing can be incorporated easily into (existing) installations. The parts, which are exposed to the flow of the materials, are made of extremely wear-resistant materials. This makes the system very suitable to de-iron extremely abrasive materials. A slip-on gear motor drives the separation drum. Next to the standard model, which is provided with a ceramic magnet system, these models can be supplied with a very powerful neodymium magnet system.

Supplied as standard with ceramic magnet systems. For versions equipped with Neodymium magnet systems, add "/ND" to the article number.

Other dimensions on request..

BM Magnetic separators WETDRUM

The Magnetic WETDRUM separator is used for the separation of iron deposits from sand / silt flows. Used during sand reclamation and for cleaning of contaminated soil.

The sludge flow is distributed through an inlet tank and flows underneath the Magnetic drum, ferrous particles are attracted to the magnet and separated from the sludge. The cleaned sludge flow proceeds to the next process step.

The WETDRUM is designed with two sectors: a magnetic and a non-magnetic. The stainless steel drum rotates around the static magnet, which is responsible for the transport of the iron parts. Depending on the particle size, the Wet drum is executed with ceramic or high powered Neodymium “rare earth” magnets.The intensity of the magnetic field can be adjusted,

in order to achieve the desired result.

WETDRUM system is often used in combination with other magnetic systems, such as: Over belt - Head pulley - Drum magnets and Eddy-Current non-ferrous separators to ensure optimal iron removal and to maximize the yield of production.