Separation Systems

Industrial separation systems

Permanent drum magnets

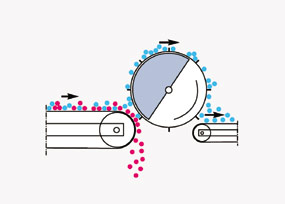

Drum magnets, also called separation drums, contain two sectors - one magnetic and the other not. There is a drum which rotates around the outside of these and over which the material flows or is dropped. To assist the separation process, the drum is fitted with idlers. The material is dropped onto the magnetic sector of the drum, and, because of the magnetic field, the ferrous particles stick to the drum. They only fall off when the magnetic sector is left and can therefore be collected separately. The illustrations on this page will help clarify

Drum magnets, also called separation drums, contain two sectors - one magnetic and the other not. There is a drum which rotates around the outside of these and over which the material flows or is dropped. To assist the separation process, the drum is fitted with idlers. The material is dropped onto the magnetic sector of the drum, and, because of the magnetic field, the ferrous particles stick to the drum. They only fall off when the magnetic sector is left and can therefore be collected separately. The illustrations on this page will help clarifythe principle. The drum is manufactured from stainless steel and has a rotating and a stationary axle. The rotating axle drives the drum, the stationary one is used to position the magnetic field. The magnetic field covers 180°. Bearing blocks are supplied.

Drum magnets are equipped with a permanent ceramic magnet system. The types with drum diameters of 215 and 315 mm can also be supplied with the extra powerful Neodymium magnet system. All versions are virtually maintenance free.

Further dimensions on request.