Separation Systems

Industrial separation systems

Automatic chute magnets

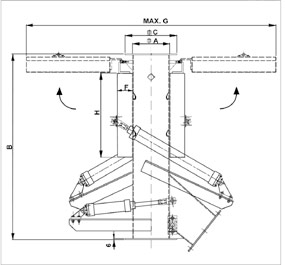

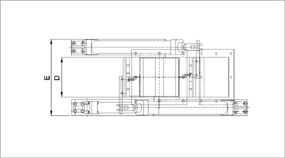

Automatic chute magnets are executed with a pneumatic operated cleaning facility. The housing has an integrated valve box for removal of the attracted iron contamination. These magnet Systems are especially developed for Separation, during "free fall", of powdered raw materials since the change of bridge building is practically zero. The cleaningcycle can be activated after stopping the material flow, by a pushbutton or on request by an electrical pneumatic valve which successively rotates the diverter and turns the magnets away from the housing, The iron contamination falls outside the System through the valve box outlet. Now the magnets turn back against the housing and the valve rotates back to its original Position. The sanitary housings are completely build out of stainless steel AISI304 and are extremely suitable for the food - and pharmaceutical industry, and other applications where high demands on hygienic circumstances are required. The Square in- and outlets are provided with flat undrilled flanges. The Systems are Standard provided with two pieces powerful ceramic FDA plate magnet. They can also be supplied with neodymium plate magnets. In this case the article

Automatic chute magnets are executed with a pneumatic operated cleaning facility. The housing has an integrated valve box for removal of the attracted iron contamination. These magnet Systems are especially developed for Separation, during "free fall", of powdered raw materials since the change of bridge building is practically zero. The cleaningcycle can be activated after stopping the material flow, by a pushbutton or on request by an electrical pneumatic valve which successively rotates the diverter and turns the magnets away from the housing, The iron contamination falls outside the System through the valve box outlet. Now the magnets turn back against the housing and the valve rotates back to its original Position. The sanitary housings are completely build out of stainless steel AISI304 and are extremely suitable for the food - and pharmaceutical industry, and other applications where high demands on hygienic circumstances are required. The Square in- and outlets are provided with flat undrilled flanges. The Systems are Standard provided with two pieces powerful ceramic FDA plate magnet. They can also be supplied with neodymium plate magnets. In this case the articlenumbers have added "/ND to them. Adaptor pieces for deviating pipes can be supplied on request.

Further dimensions on request.