Separation Systems

Industrial separation systems

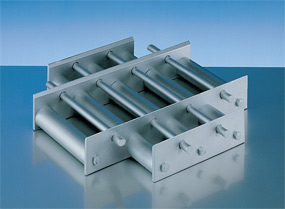

Permanent magnet grids in ceramic or neodymium version

Permanent magnet grids are placed in pipeline systems, hoppers, chutes, etc., to separate ferrous particles from materials flowing past the grid.

To ensure durability against corrosion and wear and to supply good mechanical strength, all parts of the casing that come in contact with the material to be decontaminated are made from stainless steel (AISI 304). By carefully calculating the dimensions of the entire system, the resistance to the material flowing through is small and the chance of bridges forming is minimal. For better matrial flow, the magnetic grids are equipped with distance shafts.The permanent magnet grids with neodymium magnets are suitable for temperatures up to 80°C. For applications where a higher tempuratures is required, magnet grids fitted with ceramic magnets can be supplied. These can be used to temperatures up to 150°C.

The tables below gives an overview of the standard range. If required, non-standard sizes and/or specifications can be supplied on order.

All versions supplied as standard with distance shafts, with the exception of the BM 25.100 and BM 25.101 (without distance shafts).

For the version with ceramic magnets does not apply to the part number of additional ".... / ND".

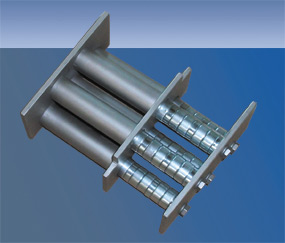

Permanent magnet grids 'easy clean'

Magnet grids can be supplied in a special "easy-clean" version. These grids are equipped with an extractor. The stainless steel casing makes it possible that the magnetic grid can be easily cleaned. When the magnet is pushed out of the extractor, the tightened metal particles come off, so that the entire system can be easily cleaned or rinsed.

Magnet grids can be supplied in a special "easy-clean" version. These grids are equipped with an extractor. The stainless steel casing makes it possible that the magnetic grid can be easily cleaned. When the magnet is pushed out of the extractor, the tightened metal particles come off, so that the entire system can be easily cleaned or rinsed. The "easy-clean" version is available with magnet grids in a square or rectangular shape.

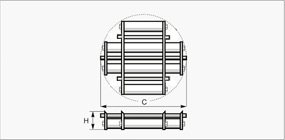

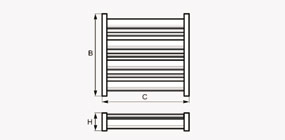

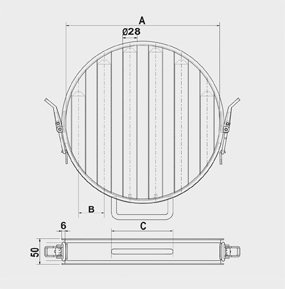

Permanent magnet grids, round with Jacob flange, easy-clean type in neodymium (NdFeB) version

The new permanent magnet grids, equipped with neodymium magnet material of quality ND48H (Art. No. BM 25. 120/ND to BM 25. 124/ND) and ND40H (Art. No. BM 25. 126/ND and BM 25. 128/ND), guarantee temperature resistance up to 120 °C with improved magnetic and physical properties. With the Jacob flange provided, the grids can easily be integrated into existing pipelines or installed at the end of the product flow.

The “easy clean”-version allows easy and quick cleaning by pulling the magnet system out of the casing.

- Suitable for ATEX zone 21 + 22

- Clearance between the bars: 22 mm

Quality ND48H = apparent remanence: 13,800 to 14,100 Gauss

Quality ND40H = apparent remanence: 12,600 to 13,000 Gauss