Magnets and magnet systems

Permanent magnetic material

Magnetising methods and technical specifications

Without magnetic materials, our society would be a lot different. In spite of the fact that people do not actually notice, the average household uses many, many magnets. For example, the ones in the electric motors in the various pieces of kitchen apparatus, in docks, and in audio/video equipment. But do not forget the magnetic catches on cupboard and refrigerator doors, magnetic sensors for security systems (sometimes in conjunction with reed contacts) and automotive applications.

Magnets are also used in scores of places in industry, for example, for extracting ferrous contamination from raw materials, for hoisting heavy metal objects or for damping pieces of work on metal working machines. For industrial applications, often a lot of magnetic force is required which leads to the development of complex magnet systems.

Types of magnetic materials

Development of magnetic materials has not come to a halt. Many modern technologies could not have been created with conventional magnets. Modern magnetic materials in comparison with the "antique" magnets are, to a large degree, permanently magnetic. For a large number

of them, a life-Iong magnetic properties guarantee is given for normal use. The modern magnetic materials from Bakker Magnetics are supplied in many forms, blocks, discs, bars, rings, etc. There are also flexible magnetic materials such as magnetic foil and strips.

Three main types of modern magnetic materials are recognised and these are:

1. ceramics,

2. those based on "rare earths" ,

3. steel.

Applications

In general, the application areas for the various magnetic materials do not vary or vary very little from each other. Naturally, each type gives different possibilities for miniaturising products, increasing efficiency or other important aspects.

Specific properties

Which material is most suitable for which application? Answering this question depends on the requirements people place on the magnet such as the space, magnetic power, mechanical considerations, price/specification factors, etc.

The operating temperature at which the magnet has to perform is also very important. With extreme high or low operating temperatures, the magnetic properties can be considerably reduced or even disappear completely. By using thecorrect material, these sorts of situations

can be avoided.

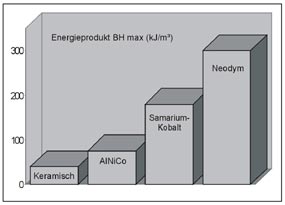

The table below gives a comparison of the most important properties of modern magnetic materials.

Magnetising methods

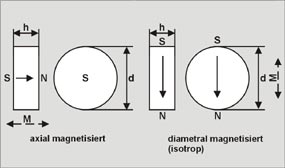

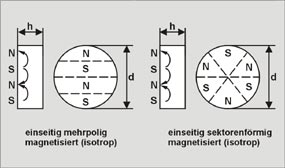

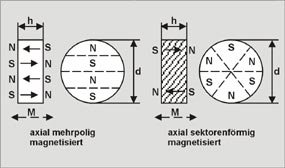

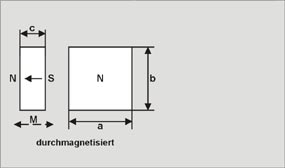

The most modern magnet materials can be magnetised in various ways. Adjacent illustrations give an idea of the most common possibilities.

Technical specifications

All values were determined at a temperature of 20 ° C.

By default, the neodymium magnets come in the marked quality BM 35. All qualities still listed are available on request.

Specifications concerning quality, models, magnetic and material properties can be changed without notice. The indicated values are serving as an orientation. Please get advice and help from our experts.

Product types and tolerances

During the manufacturing process especially when moulding and sintering, small variations in the measurements of permanent magnets cean occur. If strict tolerances have been specified for the size of the final products. The surfaces of the magnets can be ground or sawn to

the exact size. Because the hardness of the magnetic material is very high, these sawing and/or grinding operations have to be performed with special diamond-equipped tools.