Magnets and magnet systems

Permanent magnetic material

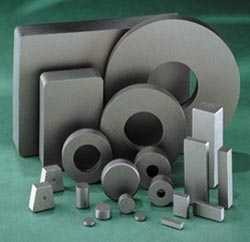

Hard ferrite magnets - ceramic -

Ceramic magnets can be used in a wide range of situations. In view of their favourable price/performance ratio, they are used in all sorts of industrial and domestic applications. The most common types of ceramic magnetic materials are the anisotropic Strontium, anisotropic Barium and isotropic Barium. The last material is far and away the favourite for low-cost applications.

Ceramic magnets can be used in a wide range of situations. In view of their favourable price/performance ratio, they are used in all sorts of industrial and domestic applications. The most common types of ceramic magnetic materials are the anisotropic Strontium, anisotropic Barium and isotropic Barium. The last material is far and away the favourite for low-cost applications. The basic material for ceramic magnets is iron oxide to which strontium or barium carbonate and a number of other materials are added to obtain the desired type. After an automatic process of measuring, grinding and mixing the raw materials, a sort of knitted substance is

obtained. This substance is pressed under the influence of an anisotropic magnetic field into the required shape. At the completion of this production phase, the product is demagnetised by reversing the magnetic field.

This is done to prevent contamination by loose magnetic particles. After the products have been dried, the extremely critical sintering process follows after which the products have been given the required mechanical properties. Before delivery, the products are magnetised to the specified level and further finished to match the specifications of the customers.

There are two types of permanent magnet materials

Isotropic und anisotropic

Isotropic magnetic materials have an identical magnetic field in all directions.

The consequence of this is that the material can be magnetised in every direction.

An anisotropic magnet is subjected to a strong uni-directional magnetic field during its

pressing. The magnetic properties are the strongest in this direction.

Dimension and tolerances

- isotropic execution -

Ceramic disc magnets, isotropic

Ceramic block magnets, isotropic

Ceramic ring magnets, isotropic

Other dimensions on request.

Magnetising methods and technical spedifications your find here