Separation Systems

Magnet systems for the food and pharmaceutical industries

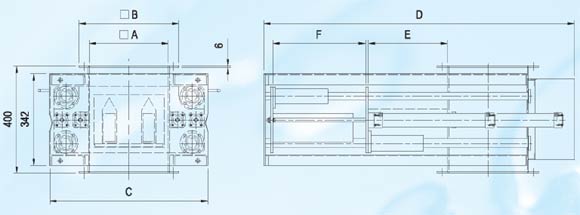

Permanent magnet systems in housing - type POWER-MAG - automatic

The POWER-MAG can also be supplied in a remote-controlled self-cleaning version. The product flow needs to be interrupted before activating the cleaning cycle. After the activation of the cleaning cycle by an electrically-operated valve two pneumatic cylinders slide the magnet system and stainless-steel sleeves from the housing. Once the entire magnet unit has been slid

The POWER-MAG can also be supplied in a remote-controlled self-cleaning version. The product flow needs to be interrupted before activating the cleaning cycle. After the activation of the cleaning cycle by an electrically-operated valve two pneumatic cylinders slide the magnet system and stainless-steel sleeves from the housing. Once the entire magnet unit has been slidfrom the housing two further pneumatic cylinders slide the magnetic units clear from the sleeves; the iron particles are then released, and collected via an iron-particle outlet. The magnet system is then returned to its original position, and is once again ready for use.

All pneumatic components are suitable for use in the food industry. The system is fitted with a control cabinet, inclusive of a compressed-air set. A pushbutton in the control cabinet can be used for the local operation of the cleaning system.

SPECIFICATIONS

Execution automatic cleaning - permanent magnet -

Overall height: 400 mm

Material: stainless steel grade 1.4404

Connection flanges: equipped with pre-drilled flat flanges

- The magnet units are moved using sliding sleeves on slide rods

Operating pressure, pneumatic system: 6 bar

- Remote control by means of an electrically-operated valve; input signal 24 VDC

- In the event the air pressure falls away the magnet units remain in the housing

- All moving parts are shielded by stainless steel guards

- The guards can be removed for inspection or maintenance

- The outlet for the discharge of the separated iron particles is fitted with a flange

- The rear of the housing is equipped with an earthing clamp

- Equipped with CE label

Surface treatment: electrolytic polishing

The standard magnet systems for the food and pharmaceutical industries are fitted with flat pre-drilled square connection flanges. A wide range of standard adapter pieces are available for the integration of these systems in an existing pipe. One end of these adapter pipes is fitted with

a pre-drilled square flange mating with the flange on the magnet system. The other end is fitted with a flat connection flange with a hole pattern in accordance with DIN2576.

Non-standard adapter pipes are available on request.