Separation Systems

Magnet systems for the food and pharmaceutical industries

Permanent magnet systems in housing - type POWER-MAG

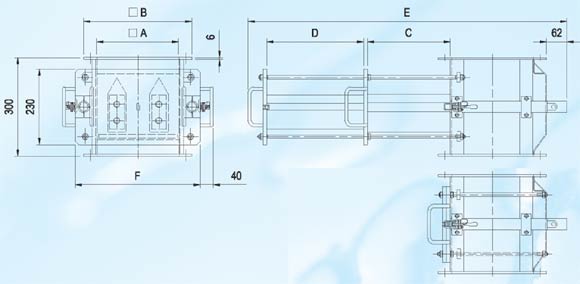

This revolutionary model has been especially designed for applications which require a combination of a low overall height, a powerful magnet system in the product flow, and a minimal risk of bridge-building. The increased distance between the magnetic units as compared to conventional grid magnets renders this system suitable for use with products which do not flow freely and/or readily adhere to or accumulate on surfaces. This system is also ideally suited to the separation of iron particles from coarser products or hygroscopic raw materials.

This revolutionary model has been especially designed for applications which require a combination of a low overall height, a powerful magnet system in the product flow, and a minimal risk of bridge-building. The increased distance between the magnetic units as compared to conventional grid magnets renders this system suitable for use with products which do not flow freely and/or readily adhere to or accumulate on surfaces. This system is also ideally suited to the separation of iron particles from coarser products or hygroscopic raw materials.The magnetic units are integrated in stainless-steel sleeves, which are also referred to as extractor. The peaked upper surface of each sleeve reduces the risk of the accumulation of product and, ultimately, bridge-forming.

The cleaning process is semi-automatic. The product flow is interrupted. After releasing the quick-action clamps the magnet system and stainless-steel sleeves are slid from the unit using the handles fitted to the sides of the intermediate panel. Once the entire magnet unit has been slid from the housing the magnetic units can be slid out of the sleeves using the handles on the front panel. The iron particles are then released by the sleeves without falling into the housing, and can be collected. The magnet system is then returned to its original position, and is once again ready for use.

SPECIFICATIONS

Execution: semi-automatic cleaning permanent magnet

Overall height: 300 mm

Material: stainless steel grade 1.4404

Connection flanges: equipped with pre-drilled flat flanges

- The rear of the housing is equipped with an earthing clamp

- Equipped with CE label

Surface treatment: electrolytic polishing

The standard magnet systems for the food and pharmaceutical industries are fitted with flat pre-drilled square connection flanges. A wide range of standard adapter pieces are available for the integration of these systems in an existing pipe. One end of these adapter pipes is fitted with

a pre-drilled square flange mating with the flange on the magnet system. The other end is fitted with a flat connection flange with a hole pattern in accordance with DIN2576.

Non-standard adapter pipes are available on request.