Sheet separators

to spread sheets

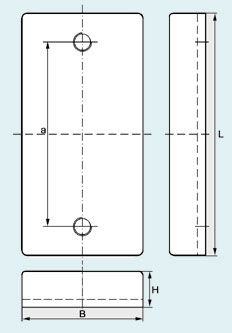

Sheet Separators

Magnetism is widely used in industry to perform activities more efficiently and more simply. This is certainly the case in construction firms where steel plates are handled. It is well known that taking just one sheet can be a relatively time-consuming business which can hold up the work especially with series production. With BM sheet Separators, the individual sheets can be directly picked up of a Stack.

Magnetism is widely used in industry to perform activities more efficiently and more simply. This is certainly the case in construction firms where steel plates are handled. It is well known that taking just one sheet can be a relatively time-consuming business which can hold up the work especially with series production. With BM sheet Separators, the individual sheets can be directly picked up of a Stack.A BM sheet Separator consists of a rust-resistant steel casing which contains a magnet System of anisotropic ceramic permanent magnetic elements. The casing and the magnet System are held in position by a steel rear plate. When a stack of steel sheets are placed in the field of influence of the sheet Separator, the magnetic field created by the sheet Separator separates them automatically so the sheets can be taken from the stack one by one very easily.

The number of possibilities for BM sheet Separators is unlimited. They can be used singly or in multiple combinations. The illustrations give a good impression of this. Which steel plate Separation System should be used in a particular Situation depends on a number of factors:

- the thickness of the sheets,

- the dimensions of the sheets,

- the height of the stack,

- the surface quality of the sheets,

- the conditions of the sheets (dry, oily, damp, etc.).

To achieve the Optimum Separation of the sheets, the height of the stack should not be more that 10 to 20% of the height of the sheet Separator. If sheets are to be taken from the stack other than by hand, for example by an automated process, offen multiple sheet Separators

will have to be positioned around the stack. BM sheet Separators are available in more than twenty different Standard sizes. For specific applications, they can also be supplied in other sizes on request.

Product video

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

Sheet separators with neodymium magnets

Practical application

Number and size of the individual sheet separators depend on the following factors:

- Thickness and size of the plates

- Height of the stack

- Surface condition of the sheets

- State of the sheets (dry, wet, etc.)

Please note, that the number of systems must be doubled.when sheets are oiled.